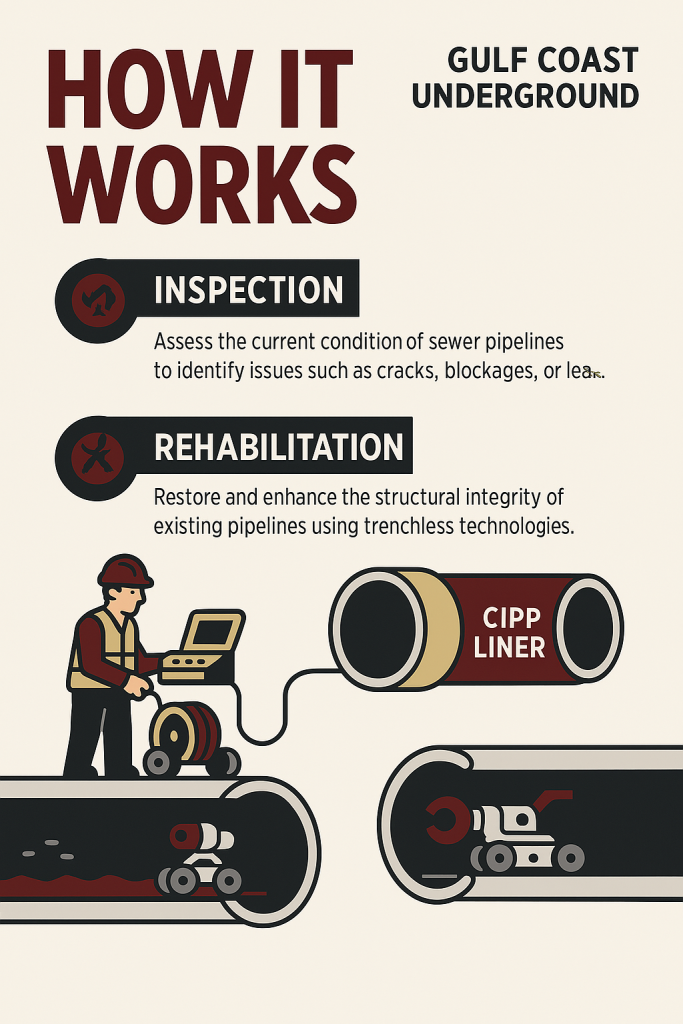

Inspection and Evaluation

The objective is to assess the current condition of pipelines to identify issues such as cracks, blockages, or leaks using the following methods

Closed-Circuit Television (CCTV) Inspection: Technicians insert specialized cameras into the pipelines to capture real-time footage, allowing for detailed visual assessments without excavation.

Flow Monitoring: Devices are installed to measure the flow rate within the sewer system, helping detect irregularities indicative of blockages or leaks.

Smoke Testing: Non-toxic smoke is introduced into the sewer lines to reveal sources of inflow and infiltration, such as cracks or illegal connections.

SSES: Sewer System Evaluation Surveys identify defects, infiltration and inflow to help prioritize repair and improve system performance to prevent backups and environmental issues.

Manhole Inspections: Our team performs both Level 1 and Level 2 inspections to evaluate the structural integrity of the manhole.

Rehabilitation & Repair

Restore and enhance the structural integrity of existing pipelines using trenchless technologies, minimizing surface disruption and address specific defects or damages within the system to restore optimal functionality.

Cured-In-Place Pipe (CIPP): A resin-saturated liner is inserted into the damaged pipe. Once in place, the liner is cured using heat or UV light, forming a new, seamless pipe within the old one.

Pipe Bursting and Pressure Pipe Rehabilitation: A resin-saturated liner is inserted into the damaged pipe. Once in place, the liner is cured using heat or UV light, forming a new, seamless pipe within the old one.

Manhole and Wet Well Lining and Restoration: A resin-saturated liner is inserted into the damaged pipe. Once in place, the liner is cured using heat or UV light, forming a new, seamless pipe within the old one.

Lateral and Main Grouting: A resin-saturated liner is inserted into the damaged pipe. Once in place, the liner is cured using heat or UV light, forming a new, seamless pipe within the old one.

Shotcrete and Coatings: Utilizing advanced robotic cutters, technicians can remove intrusions, reinstate service laterals, and perform precision cutting within rehabilitated pipelines.

By integrating these specialized services, Gulf Coast Underground ensures that wastewater infrastructure is maintained and restored efficiently, extending the lifespan of sewer systems while minimizing environmental and community impact.